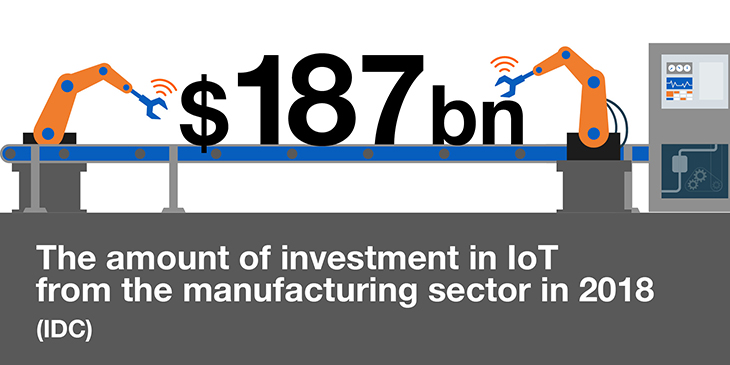

Manufacturing is expected to spend $189 billion on IoT in 2018, according to IDC. It will be largely focused on operations and production asset management and is expected to rise for the foreseeable future as manufacturing sees the benefits of a connected world.

The Internet of Things (IoT) has opened manufacturing to new entrants. At the same time, the big established players have found IoT adoption difficult as they can't play alone. Markus Meukel, VP IoT at McKinsey maintains that we'll see an ecosystem of partnerships developing to get over this barrier.

The code to tapping into the power of IoT

The connected products market will be worth up to $457 billion by 2020 according to IDC. With such big opportunities emerging, it may seem odd that manufacturers aren't rushing to join the connected revolution.

The answer is simple:

Manufacturers are all too aware that they need to re-think their business models using digital technologies and scale up fast to grasp these new opportunities. But they need advice from experienced consultants and technology players to advance, according to Meukel. They need to be shown the importance of putting the different building blocks, strategy and infrastructure in place, so they can mobilize their companies and make them more agile.

Everything comes with a service

Products can now be copied easily, which has put manufacturers under a growing threat from consumerization. They therefore need to enrich their business models to survive.

One company that has done this successfully is e.l.m. leblanc, part of the Bosch Group, which operates in the residential and industrial markets for boilers and ventilation products. e.l.m. leblanc has been connecting boilers since 2004. Back then, it equipped its boilers with a "black box" designed to send a boiler's very last piece of data before it died, so it could run a post mortem.

Fast forward more than a decade. Data is now central to e.l.m. leblanc's IoT and Industry 4.0 strategy.

Orange Business, for example, has delivered a customized remote monitoring IoT platform for e.l.m. leblanc's boilers, built on Microsoft Azure cloud and utilizing the Orange LoRa network.

The Orange remote monitoring solution collects the boiler's data and automatically alerts technicians of any malfunctions. This enables efficient maintenance intervention, with predictions on the probable causes of failure based on real-time data analytics. Preemptive alerts can also be raised by the platform through predictive maintenance algorithms.

Bricard said it took time to convince everyone that change was necessary, and it was essential to embrace IoT and the cloud. A lot of work had to be done between departments to define new ways to carry out processes, security and validation. It also had to manage the behavior of customers, who needed to understand this connected world. e.l.m. leblanc, for example, provides its own after-sales services as well as selling connected boxes to servicing partners.

Bricard said working with partners, such as Orange Business, was essential to make the journey to a service model easier and link the dots in its ecosystem.

Connected services can start simple

So, how can companies move off the proof-of-concept (PoC) starting blocks and efficiently scale up like e.l.m. leblanc? The successful transformation cases in IoT that McKinsey has surveyed have started very simply with an area such as remote monitoring. The value step from planned to predictive maintenance is actually very little, even though the latter is much more complex, according to Meukel.

Hear more from McKinsey's Markus Meukel, Emmanuel Bricard, CIO of e.l.m. leblanc and Werner Reuss from Orange Business, in this exclusive webinar on how to create value from IoT.

Jan has been writing about technology for over 22 years for magazines and web sites, including ComputerActive, IQ magazine and Signum. She has been a business correspondent on ComputerWorld in Sydney and covered the channel for Ziff-Davis in New York.