According to the OECD, around 14 percent of jobs in developed countries are highly automatable, while around 32 percent will experience changes in the way they are carried out, which may require human re-skilling. The OECD’s research suggests that job threats posed by automation will be far less severe than an Oxford University report in 2013, which predicted that 47 percent of US jobs would be eaten up by computerization within 10-20 years.

Here are 7 innovative ways robots are contributing to our societies and economic development already:

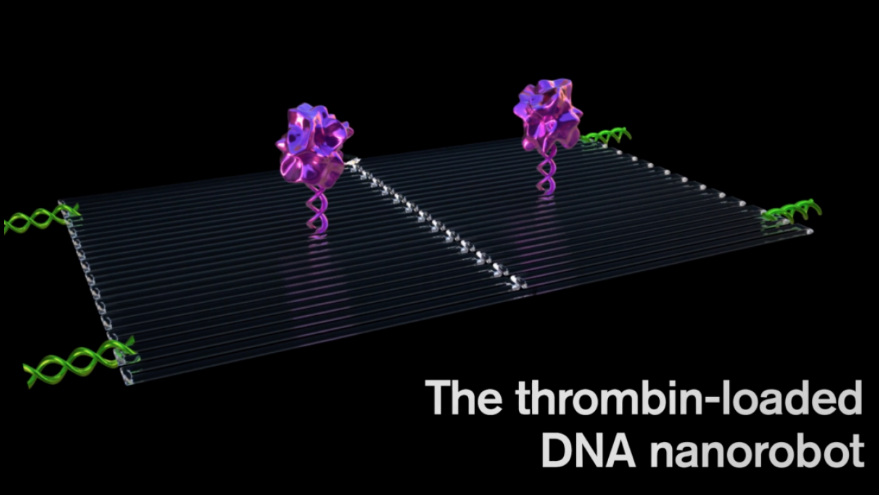

Nanobots destroy tumors

Arizona State University in collaboration with the National Center for Nanoscience and Technology (NCNST) of the Chinese Academy of Sciences has successfully programmed nanobots to shrink tumors by cutting of their blood supply. The first fully autonomous DNA robotic system for targeted therapy has the potential to be used on any type of cancer.

Helped the aged

With a global aging population, robots are becoming increasingly important at delivering efficient and cost-effective care in certain cases. Healthcare companion Pillo, for example, has been designed to enable seniors with chronic conditions to take care of their health at home. Using AI, face and voice recognition it helps patients manage their medication plans and chat to a member of their care team if required.

Steady hands for complex operations

Robots are set to change the way operations are performed, helping surgeons improve the precision, safety and accuracy of surgery on highly complex organs such as the eye. Last year, the Robotic Retinal Dissection Device or R2D2, for example, became the first robot to perform an operation on the human eye, removing a sensitive membrane.

Agribots with green fingers

The agricultural sector has been quick to adopt robots to take over some of the back-breaking chores such as weeding, pruning, spraying, harvesting and packing. Queensland University of Technology in Australia, for example, has come up with the AGBOT II. Using AI and cameras it can spot weeds and decide on the best way of eradicating them. The Fraunhofer Institute for Production Systems and Design Technology IPK in Germany is developing and testing a two armed robot that for picking cucumbers, while Robotics Plus is planning to move its robotic apple packer to commercial production. Both are designed to replace labor-intensive processes.

Kitchen helpers

Restaurants are adopting robots to wait at tables. Robots in China have been greeting guests and carrying food around for some time. Other fast food restaurants are taking up the idea. Pizza Hut, for example, is trialing Softbank’s Pepper bot in association with Mastercard at an outlet in Singapore. The bot will take orders and give out table numbers. Pizza Hut is also leading the way on a self-drive pizza delivery truck with Toyota. In the future it could not only deliver pizzas, but bots will make them on the way! Zume Pizza in the US already has vehicles that deliver pizzas baked by bots on route. And in the kitchens a bot is flipping burgers. Flippy, the first burger flipping bot designed by Miso Robotics, is working alongside staff at Caliburger in Pasadena, California.

Robot drivers

Bots are changing transportation. Renault, for example, has been showing off a robo vehicle and ride hailing system. Dubbed Renault EZ-GO, the electric autonomous vehicle can be hailed from either a permanent fixed location in cities or via a mobile app. Meanwhile, Nissan has partnered with DeNA to test their Easy Ride robot taxis in Japan. Once in the robot taxi can input what they want to do via voice and will be given recommendations on events and places to visit. On the trucking side, Uber is now transporting freight using robot trucks across Arizona, US. The Volvo robot trucks include a back-up driver.

Robot baggage handlers

Handing in baggage at an airport is one of the most stressful parts of travelling – but it may soon be a thing of the past. Meet SITA’s Leo, a fully autonomous, self-propelling baggage robot that can check in, print bag tags and transport up to two suitcases with a maximum weight of 32Kg. It can maneuver around obstacles and navigate its way in a high-traffic environment, such as an airport concourse.

Passengers first touch Leo’s ‘Scan&Fly’ bag drop interface, opening the baggage compartment doors to place bags inside. Passengers then scan their boarding passes and tags are printed to attach to the bags. When the bags are loaded and tagged the compartment door closes and Leo displays the boarding gate and departure time. Leo has been trialed at Geneva airport and is now being demonstrated around the world.

Jan has been writing about technology for over 22 years for magazines and web sites, including ComputerActive, IQ magazine and Signum. She has been a business correspondent on ComputerWorld in Sydney and covered the channel for Ziff-Davis in New York.