The pandemic, as well as its impact on the supply chain, has been a wake-up call for many organizations. It has created many different disruptions, from interruptions in production lines to reduced availability of raw materials and components. To manage supply chain risk, it is vital for organizations to be able to identify and predict these disruptions.

You can transform supply chains by addressing inefficiencies and general lack of interconnectivity and by overhauling manual processes or system configurations. Data inefficiencies, where data is misaligned between customer and supplier, also cause problems. So, too, do policy and people inefficiencies, which create blockages and siloes in an organization. For example, in logistics, companies have often had separate systems to manage transportation, warehousing and third-party logistics.

Many supply chain processes are still carried out manually by workers, which creates many of these inefficiencies. Manual data entry exercises are repetitive and, as such, can be prone to human error. All these inefficiencies can snowball and build up to create problems and bottlenecks in the supply chain. With many companies still relying on just-in-time supplies, in the event of disruption, they need better visibility of inventory and production forecasts across all sites so they can shift materials to high-priority locations. With siloed systems and no real-time data insights, it’s difficult to react effectively to a crisis.

What is hyperautomation, and what does it do?

Hyperautomation, which includes artificial intelligence (AI)-enabled robotic process automation (RPA) plus other digital technologies like IoT, intelligent document processing, chatbots, mobile applications and blockchain, can help address challenges and mitigate inefficiencies in the supply chain.

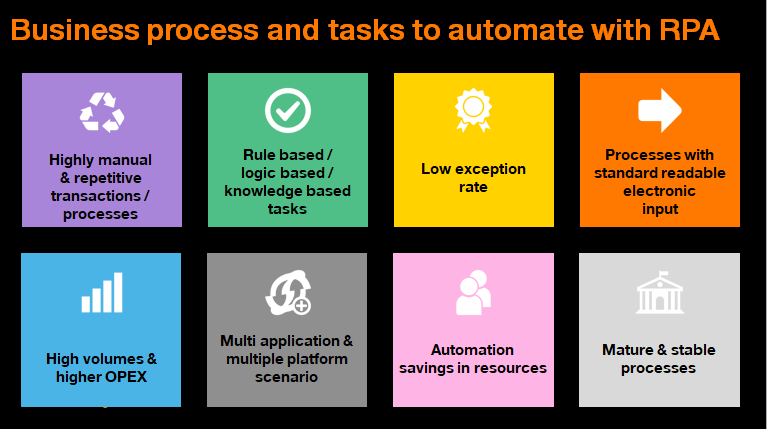

RPA comprises bots that extract data from one application and transfer it into another. It plays a crucial role in delivering hyperautomation: RPA is ideally suited to executing scripted tasks that are routine, repetitive, rule-based and predictable. Furthermore, it can operate around the clock, faster, with fewer errors and at less cost than human workers are able to perform the same processes or tasks.

However, just 42% of companies in a new report published by Orange Business and Longitude say they have increased their level of automation to handle growing data volumes. They do acknowledge that they need it, though: 80% say they believe that automation is vital to empowering both employees and supply-chain partners with data insights.

Gartner ranks hyperautomation as one of the top eight supply chain technology trends for 2020 and beyond. Hyperautomation refers not only to the tasks and processes that can be automated but also to the level of automation. It’s worth noting, though, that RPA and hyperautomation are separate solutions: RPA is a non-invasive way of integrating legacy and new business workflow solutions – but it is only suitable for simple, routine, repetitive and stable tasks.

How can the supply chain benefit from hyperautomation?

AI-enabled supply chain planning and execution systems can help mitigate risk in the supply chain. They can increase the visibility of supply chain systems, enabling businesses to act and make decisions using real-time information. However, it is important to remember that processes are not always simple, routine, repetitive and stable. This is where complementary technologies, like machine learning or chatbots (where the intervention of a supervisor is needed) come into their own.

AI and machine learning (ML) are continuous learning systems that take data collected from within the supply chain and update automated systems dynamically, with an exponential effect. This reduces the time required to build and deploy new process models so that supply chain process management gets faster and more efficient on an ongoing basis.

These types of marginal gains are precious. The benefits of a couple of seconds saved here and there on individual processes might seem relatively small at first: but over time and over tens of thousands of transactions, they all add up into a significant, overall improvement.

Hyperautomation is already being adopted in daily supply chain operations around the world, and RPA is being used for all kinds of functions. It is being used to automate manual data entry functions, generate supply chain status updates and perform system-to-system audit functions. Complex supply chain functions can now be processed more quickly and more easily across ERP, transportation and warehouse management systems. It can help companies save hundreds of staff hours per day on repetitive tasks, and by helping eliminate paperwork, it even brings environmental benefits.

An essential supply chain technology moving forward

Over time I expect to see hyperautomation become central to an end-to-end supply chain strategy, and the question will be just how much automation will be involved in the supply chain. Or, as Gartner puts it, how companies will automate the process of creating new RPAs and “scale beyond the initial few low-hanging fruits of routine processes [that] cannot be solved by a single tool or with siloed strategies.”

It’s been predicted that by 2024, companies will be able to cut operational costs by as much as 30% by combining hyperautomation technologies with redesigned operational processes. I see every chance that this will accelerate as companies rethink supply chains in the aftermath of COVID-19 and look to automation tools to help them mitigate risk.

In my next blog, I will discuss specific processes within a supply chain where hyperautomation, RPA and AI can deliver targeted benefits.

Find out how you can optimize your global supply chain by using real-time data to create a more agile and responsive ecosystem.

Dheeraj has over 18 years of digital transformation experience working with large organizations in multiple industries. He has helped organizations build specific digital point solutions utilizing niche technology levers like RPA, AI and analytics. As a Global RPA Practice Head at Orange Business, Dheeraj is responsible for running multiple projects within IT service management, supply chain and logistics domains for Orange customers.